Types of polyisoprene that are used as natural rubbers are classified as elastomers. Currently, rubber is harvested mainly in the form of the latex from the Pará rubber tree (Hevea brasiliensis) or others. The latex is a sticky, milky and white colloid drawn off by making incisions in the bark and collecting the fluid in vessels in a process called «tapping». Manufacturers refine this latex into the rubber that is ready for commercial processing. The manufacturing process of fluorosilicone rubber involves the polymerization of siloxane monomers with fluorinated compounds.

Its impermeability to gases ensures reliable performance in sealing components such as valves, gaskets, and engine seals, where maintaining pressure and preventing leaks is important. The discovery of rubber during the Industrial Revolution marked a significant turning point in material science, offering a versatile solution for sealing and insulation in numerous industrial applications. Rubber’s ability to adapt to diverse conditions has made it a revolutionary industrial material, indispensable in sealing components for industries ranging from automotive to construction. Natural rubber production begins by tapping rubber trees4 to extract latex.

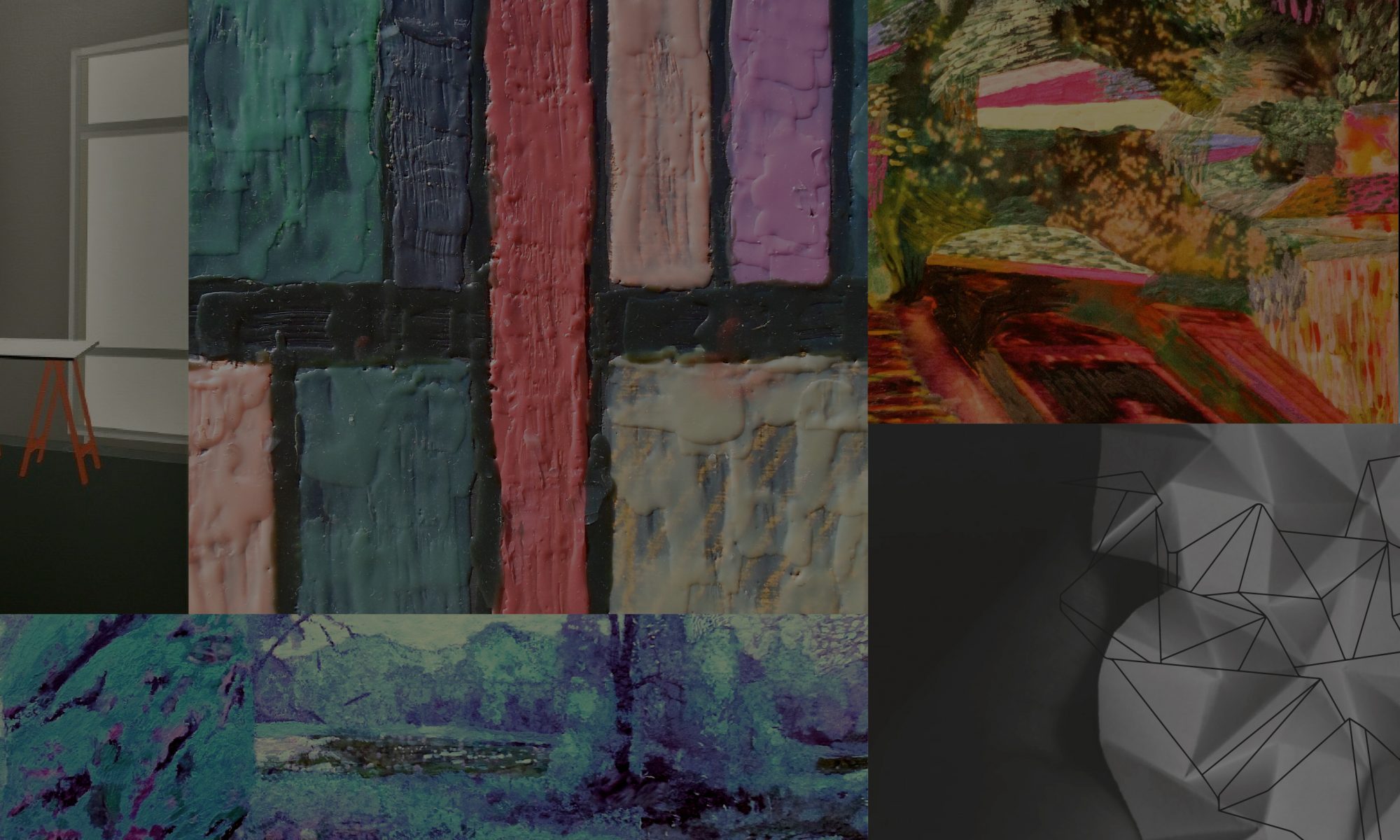

Natural rubbers excel in elasticity and flexibility, while synthetic variants like nitrile, neoprene, and SBR are tailored for specific purposes, such as chemical or weather resistance. This classification ensures targeted solutions for industrial and consumer needs. According to a report by Statista, synthetic rubber had a market value of over 33 billion U.S. dollars as of 2024.

- Nitrile rubber is also a fundamental material in protective gloves, particularly in medical and laboratory environments.

- The type of rubber best suited to an application depends on its specific requirements, including factors such as temperature range, chemical exposure, flexibility, and durability.

- It is resistant to oils, fuels, and high temperatures, making it perfect for the aerospace and automotive industries.

- The manufacturing process of synthetic rubber begins with the polymerization of petroleum-derived monomers like butadiene and styrene.

- Smallholders’ lump is produced by smallholders, who collect rubber from trees far from the nearest factory.

Properties of Rubber

The term “elastomer” is derived from “elastic” and “polymer,” emphasizing their nature as stretchable materials that extend and return to their original shape. This unique property makes them ideal for applications requiring both flexibility and durability. The benefits of using rubber material are flexibility and elasticity, water and weather resistance, and insulation properties. These qualities make rubber necessary in a wide range of industrial and consumer applications. Silicone rubber is also used in automotive engines for hoses, gaskets, and vibration dampers.

What are the Main Uses of Styrene Butadiene Rubber?

This enriches biodiversity, fortifies local food security, and shields plantations from pests and diseases. Rubbers are called elastomers because they are highly elastic polymers capable of returning to their original shape after being stretched or compressed. This property is due to rubber’s amorphous structure, which allows it to deform under stress and revert to its original form once the stress is removed.

What is the Manufacturing Process of Natural Rubber?

These methods conserve water and prevent hazardous runoff, which might transport pollutants to nearby bodies of water. Continual cultivation can erode the soil’s quality, reducing its fertility. This is further exacerbated when plantations use heavy pesticides and fertilizers, adversely affecting is rubber biodegradable the soil’s structure and overall health. We cater to various industries such as construction, aviation, agriculture, and marine. Quality is our priority, ensuring you get the best possible experience and product.

After polymerization, the rubber is compounded with stabilizers, carbon black, and other additives. The compound is then vulcanized to improve its strength and durability, making it suitable for a wide range of applications. The four types of field coagula are «cuplump», «treelace», «smallholders’ lump», and «earth scrap».

- The soil requirement is well-drained, weathered soil consisting of laterite, lateritic types, sedimentary types, nonlateritic red or alluvial soils.

- Its excellent insulation properties make it an important material in electronics, particularly for protective covers and thermal interface materials.

- The latex from many trees is thenfiltered, washed, and reacted with acid to make the particles of rubbercoagulate (stick together).

- After polymerization, the rubber is compounded with stabilizers, carbon black, and other additives.

- In the cultivation of Hevea, the natural contours of the land are followed, and the trees are protected from wind.

- The steps and precautions that should be taken for proper installation of rubbers include proper surface preparation, correct selection of rubber type, and proper alignment.

What is Rubber? The Facts and the Properties of Rubber

On the other hand, synthetic production uses petrochemicals, which, if mismanaged, can also pollute water. Moldable rubber parts are formed by placing rubber compounds into molds, where they are heated to cure and take the mold’s shape. This technique allows for more complex shapes and is better suited for large production runs or intricate designs.

Because rubber does not dissolve easily, the material is finely divided by shredding prior to its immersion. Rubber is used in various industries, from machinery sealing to electrical insulation and automotive parts. Its versatility supports its role as an important component for industrial equipment, consumer goods, and infrastructure. The material’s adaptability meets evolving industrial and environmental challenges, reinforcing its importance in modern life. It is usual to tap a panel at least twice, sometimes three times, during the tree’s life.

In many products, rubber is added as a protective coating for either weatherproofing or shockproofing. The manufacturing process of silicone rubber involves the polymerization of siloxane monomers in the presence of a catalyst. The polymer is then mixed with fillers and other additives to improve its properties. It is vulcanized using heat or a chemical curing agent to enhance its strength, flexibility, and thermal stability. The material is then molded into seals and gaskets for various applications. The main uses of natural rubber include applications in the rubber industry in tires, seals and gaskets, footwear, and industrial machinery.

The rubber/acid mixture is what gives rubber plantations, markets, and factories a strong odor. The economic life of rubber trees in plantations is around 32 years, with up to 7 years being an immature phase and about 25 years of productive phase. Rubber’s stress–strain behavior exhibits the Mullins effect and the Payne effect and is often modeled as hyperelastic. Because there are weakened allylic C–H bonds in each repeat unit, natural rubber is susceptible to vulcanisation as well as being sensitive to ozone cracking.

Natural rubber production

Each has significantly different properties.48 Some trees continue to drip after the collection leading to a small amount of «cup lump» that is collected at the next tapping. Tree lace and cup lump together account for 10%–20% of the dry rubber produced. Latex that drips onto the ground, «earth scrap», is also collected periodically for processing of low-grade product. You can get customized rubbers from specialized manufacturers like Rubberxpert, which tailor rubber products to meet specific requirements in various industries.

For the rest of this article, we’ll concentrate mostly on natural rubber. The soil requirement is well-drained, weathered soil consisting of laterite, lateritic types, sedimentary types, nonlateritic red or alluvial soils. The parallel chains of stretched rubber are susceptible to crystallization. This takes some time because turns of twisted chains have to move out of the way of the growing crystallites. Crystallization has occurred, for example, when, after days, an inflated toy balloon is found withered at a relatively large remaining volume. Where it is touched, it shrinks because the temperature of the hand is enough to melt the crystals.

The polymerization process occurs in a solvent or liquid phase, resulting in a high-molecular-weight rubber. The rubber is then compounded with antioxidants, processing oils, and other additives to improve its properties. The material is then vulcanized for further processing into desired forms, such as seals and gaskets. Natural rubber comes from the latex of rubber trees, while synthetic rubber is made through chemical processes using petroleum-based products.

What Industries Rely on Rubber Products?

Its thermal stability and elastic properties make it outstanding for automotive and industrial applications, particularly seals and gaskets, where durability and flexibility are important. The manufacturing process of nitrile rubber involves the polymerization of butadiene and acrylonitrile in an emulsion or solution process. The polymer is then compounded with carbon black, oils, and stabilizers to enhance its resistance properties. The material is vulcanized to increase its strength and flexibility, making it ideal for use in seals and gaskets. In material engineering, heat-resistant rubber, such as vulcanized rubber, is valued for its resistance to heat, chemicals, and mechanical stress. This makes it ideal for conveyor belts, vibration dampeners, and industrial seals used in harsh environments.